R&D

About the R&D Center

NEOOTO R&D Center is responsible for the successful execution

of various projects of domestic and foreign customers including

sustainable management, identification and prediction

of customer trends for the development of products that will

be responsible for the future of Neooto, establishment

of R&D strategies and product development accordingly,

cost management, technology and process management, etc.

of various projects of domestic and foreign customers including

sustainable management, identification and prediction

of customer trends for the development of products that will

be responsible for the future of Neooto, establishment

of R&D strategies and product development accordingly,

cost management, technology and process management, etc.

R&D OVERVIEW (Modularization Plan for e-PT)

-

As-Is (~`24)

-

-

5 Types of Reducers

-

e-Parking Systems

Electrification of Internal Combustion Vehicle

-

K7100kW F/f-Type

K7100kW F/f-Type -

Hyundai Accent45kW F/f-Type

Hyundai Accent45kW F/f-Type -

Hyundai Porter45kW F/r-Type

Hyundai Porter45kW F/r-Type

-

4 transmissions

-

TCU Systems

Electrification of Internal Combustion Vehicle

-

Kia Bongo100kW F/r-Type

Kia Bongo100kW F/r-Type -

Danigo EV van45kW R/r-Type

Danigo EV van45kW R/r-Type

-

-

Now (`25~)

-

- Parking mechanism stabilization

-

- Optimized design of parking mechanism

- Securing parking actuator reliability

- Stabilizing e-Parking Systems

-

- Improving Parking Actuator Performance

- Securing Act. control technology

- Securing and improving reducer reliability

-

- Expanded reducer durability/performance testing

- Systematization of reducer test data

Securing control technology and infrastructure- Stabilization of transmission components

-

- Optimized design of shifting mechanism parts

- Ensure Transmission Mechanism Reliability

- Stabilize TCU Systems

-

- Improve TCU performance (external collaboration)

- Securing TCU development technology

-

To-be (~`30)

-

Strategy Line-up selection and modularization development Potential customers: tuning / small EV / retrofit marketEstablish cooperation

among target companies Reducer + eParking

Reducer + eParking

or 2-speed transmission +

TCU (Neooto)Inverter

(Participating companies)Drive motor

(Participating companies)- PE modularization and standardization to secure price competitiveness

-

- Improving the performance of sensors/transmissions and applying optimization by motor

- Expand publicity through continuous participation in exhibitions (1-2 times/year)

- Integrated exhibition of chassis/drives/robots

- Sales/Planning/R&D Center/New Business Partnership Organization

Major R&D Areas

01. AL DIFF. CASE Technology Development

- Development of aluminum diff case

-

AL DIFF. CUP

AL DIFF. CUP

Durable strength test

Durable strength test

AL DIFF. COVER

AL DIFF. COVER

Vibration endurance test

Vibration endurance test

Item Unit Iron Casting Development Product

(Aluminum alloy)Remark Weight g 2,618 1,194 Weight reduction rate 52% or more Tensile strength Mpa Min. 600 368 - Yield strength Mpa Min. 370 316 - Elongation % Min. 3 16 - Durability performance km 30만km equivalent 30만km equivalent No issue Power endurance perform - - Total running time : 366 min No issue Power transmission efficiency % - Before test 82.8%

After test 82.5%No issue Vibration endurance performance % - Total vibration time : 48 hr No issue

- Development Goals

-

-

Replace existing cast iron (FCD600) material with AL alloy (A6061)Reduce weight

(Improve fuel efficiency) -

Secure AL alloy production technology (process)Strengthen AL alloy stiffness

and improve functionality -

Optimal shape design and analysisQuality/Price

Secure competitiveness

-

- Feature Comparison

-

Classification Conventional casting

process (FCD600)Aluminum alloy Cast process

(A380)Cold forging process

(A6061)Mechanical property Tensile strength (MPa) Min. 600 Min. 241 Min. 320 Yield strenght (MPa) Min. 370 Min. 132 Min. 280 Elongation (%) Min. 3 Min. 23 Min. 10 Density by material (g/cm3) 7.32 2.8 (2.6 times lighter than iron casting) 2.8 (2.6 times lighter than iron casting) Key features Excellent castability,

Excellent strength and friction resistance,

Excellent machining,

High weightExcellent corrosion resistance, Good castability, Low productivity High mechanical properties,

Excellent productivity,

Improved dental density,

Limited molding of complex shapesLow strength compared to cast iron

(meets required performance level)

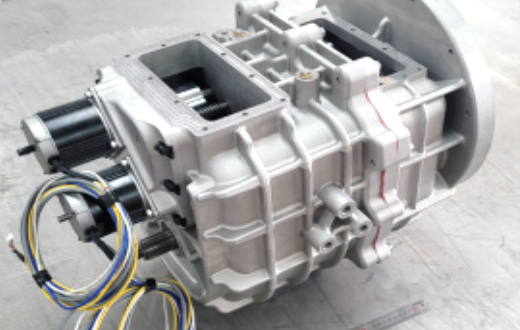

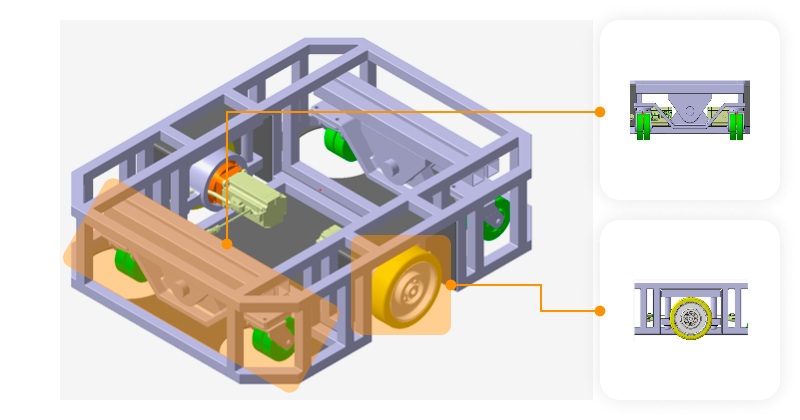

02. Developing gearshift technology for eco-friendly commercial vehicles

- Development of multi-speed transmission motorized powertrain technology for eco-friendly commercial vehicles

-

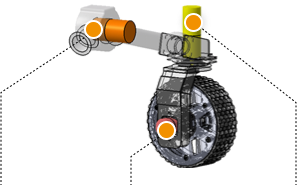

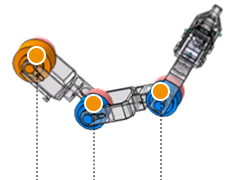

03. Developing actuator technology for robots

- Developing localization technology for rover drive components for planetary exploration through the development of self-designed reducers

-

-

- ROVER DRIVETRAIN

-

- Reducer for suspension

- Reducer for drive

- Reducer for steering

-

-

- ROBOTIC ARM

-

- Reducer for work machine

-

- Overview

-

- Project Name Material Parts Technology Development Project

- Target Vehicle Space rover and mobile robot Actuator

- Development Period -

- Purpose of development

-

-

Precision and small size applicable to robots development of own reducer

-

Development of reducer that works in space environment

-

Development of drive/ suspension/steering/articulation reducer for planetary rover

-

- Development Direction

-

- Replacing labor force due to declining population (Era of Robot)

- Securing technology for the expansion of robot applications across industries

- Accumulation of self-developed technology of precision miniature reducers for robots

- First prototype

(basic performance verification) -

- Second prototype

(productivity enhancement) -

04. Development of reducer for driving mobile robots - NEO-Exen reducer

- Smart integrated drive module

-

Purpose of development

-

Integrated drive module for mobile robots

-

Evaluation technology of drive module reducer

-

Mobile robot

Mobile robot

Research facilities

Startup / Assembly / Test facilities

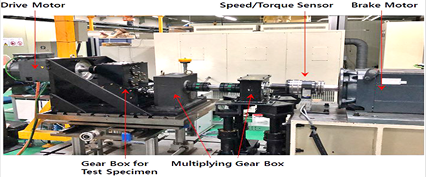

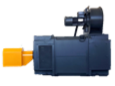

- T/M DYNAMOMETER

-

Input Motor (1Set)

Input Motor (1Set)-

- Maker (Country)

-

- AKH (Germany)

-

- Main Spec

-

- Rated Power : 160kW

- Max. Torque : 400Nm

- Max. Speed : 16,000rpm

- Air Cooling Type

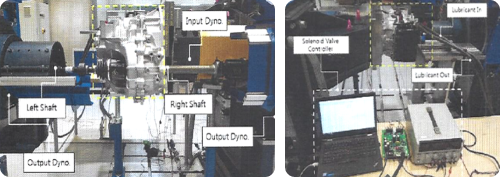

Out Motor (2Set)

Out Motor (2Set)-

- Maker (Country)

-

- SIEMENS (Germany)

-

- Main Spec

-

- Rated Power : 275kW

- Max. Torque : 10,943Nm

- Max. Speed : 2,800rpm

- Air Cooling Type

Noise Chamber (1Set)

Noise Chamber (1Set)-

- Maker (Country)

-

- VMV-Tech (Korea)

-

- Main Spec

-

- Sliding Shut Type

- Blocked Outside Noise

NVH Tester

NVH Tester-

- Maker (Country)

-

- VMV-Tech (Korea)

-

- Main Spec

-

- Channel : 16ch

- M’ment Time Data of NVH

- Analysis of Overall Level

- Analysis of Sound Quality

-

- SHIFT PERFORMANCE TESTER

-

- PROTO ASSEMBLY EQUIPMENTS

-

Oil-Pressure Press

Oil-Pressure Press Heating Chamber

Heating Chamber Air Leak Tester

Air Leak Tester

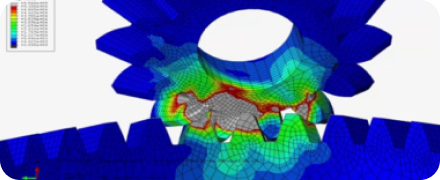

Software

| Div | Name (Maker) | Image | Q’TY | Contents |

|---|---|---|---|---|

|

2D & 3D Design |

AutoCAD (AUTODESK) |

|

14 |

|

|

CATIA V5 (Dassault Systems) |

|

3 |

|

|

|

Design / Calculation |

KISSsoft & KISSys (KISSsoft) |

|

1 |

|

|

Systems & Parts Analysis |

ABAQUS (Dassault Systems) |

|

1 |

|

|

TCU Logging & Analysis |

CANoe (VECTOR) |

|

1 |

|