About OTO Group

Corporate Identity

- SYNERGY

- Leading Group in Mobility

Precision Machining

- Forging · Turning

- Machining · Assembly

- Logistics

- Bar distribution

- PORTFOLIO

- Precision components for mobility Building a portfolio

Internal Combustion Engines

- Pinion

Gear - Differential

Assembly - Large

Gear

Eco-friendly

- Shaft

- EV Speed Reducer

- CUSTOMER

- Secure Vehicle OEM customer

Group Overview

-

- forging · cutting

-

Forging & Turning

- OTO Industry

- OTO Vina

-

- Finished processing · assembly

-

Finished Machining-Assem

- Neooto

-

- Distribution

-

Logistics

- OTO Czech

- OTO India

-

- round-rate distribution

-

Bar Distribution

- Neosteel

Global Footprint

USA

- Customers

-

-

Hyundai

-

Kia

-

Stellantis

-

MEXICO

- Customers

-

-

Kia

-

CZECH REPUBLIC

- Customers

-

-

Hyundai

-

Kia

-

KOREA

- Customers

-

-

Hyundai

-

Hyundai Transys

-

Kia

-

- Headquarters and production subsidiaries

(logistics subsidiary) -

-

OTO Industry

-

Neooto

-

CHINA

- Customers

-

-

Hyundai

-

Hyundai Transys

-

INDIA

- Customers

-

-

Hyundai

-

- Headquarters and production subsidiaries

(logistics subsidiary) -

-

OTO India

(Chennai_Logistics)

-

VIETNAM

- Customers

-

-

Toyota

-

F.C.C

-

Hyundai

-

Kia Motors

-

Hyundai Transys

-

- Headquarters and production subsidiaries

(logistics subsidiary) -

-

OTO Vina

-

BRAZIL

- Customers

-

-

Hyundai

-

INDONESIA

- Customers

-

-

Hyundai

-

Production Base Status

-

Yesan 1 Factory

-

-

-

- Info

-

- Location 8, Durumeri gil, Sapgyo-eup, Yesan-gun, Chungnam

- Area 34,226㎡

-

Major

Pinion Gear, Annulus,

DIFF ASS’Y

-

- Characteristics

-

Introduced the first SPC system in Korea

*SPC system: Statistical process control system to check defect rate in real time and prevent possible defects in advance

-

- CAPA

-

-

Pinion Gear

35 million units

per year -

Annulus

1 million units

per year

-

Pinion Gear

35 million units

-

-

Yesan 2 Factory

-

-

-

- Info

-

- Location 33, Durumeri gil, Sapgyo-eup, Yesan-gun, Chungnam

- Area 15,653㎡

- Main Products 4 Major Gears, 7th-DCT

-

- Characteristics

-

Specialized in gear grinding process, the last process of precision machining

Flexible production that performs multiple processes with existing facilities

-

- CAPA

-

-

Pinion Gear

240 million units

per year -

Speed Gear

600,000units

per year -

4 Major Gears

1.3 million units

per year

-

Pinion Gear

240 million units

-

-

Yesan 3 Factory

-

-

-

- Info

-

- Location 85, Sandan 2 gil, Sapgyo-eup, Yesan-gun, Chungnam

- Area 19,785㎡

-

Main Products

Annulus T/F Drive, B-Motor

shaft, EV Diff Drive

-

- Characteristics

-

A production facility specializing in electrification parts such as EV reducers

-

- CAPA

-

-

Annulus

2.5 million units

per year -

T/F

500,000 units

per year -

EV

400,000 units

per year

-

Annulus

2.5 million units

-

Possessing all-process automation facilities

Automation of all Neooto facilities

-

Helical gear

Helical gear

hobbing&broaching -

HOBB'G MACHINE

HOBB'G MACHINE

-

GEAR GRIND'G

GEAR GRIND'G

-

GEAR CHECKER

GEAR CHECKER

-

HEAT TREATMENT

HEAT TREATMENT

Introduced SPC (Statistical Process Control) for the first time in the industry

-

Real-time defect rate check

-

Abnormalities, Proactive equipment repair/maintenance

-

- Quality of precision machined parts

-

Quality certification status

Only HMG supplier having ‘Quality 5 Star’ in both Quality and Delivery

Hyundai Motor Company(HMG) Supplier Rating

- Quality 5.0 Stars (within the top 5%)

- Delivery 5.0 Stars (within the top 5%)

-

- Building a flexible production system

-

Flexible production system

Flexible production system enables product diversification without additional capacity

-

Internal combustion engine

-

EV

-

Hybrid

-

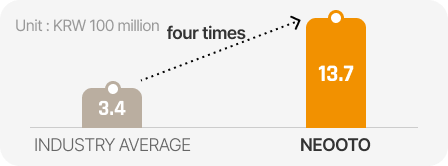

- Productivity

-

Sales per capita in 2023

Unparalled productivity through automation of all processes

GROUP SYNERGY

and overseas logistics bases

Top-tier customer network

Reduced cost rate

-

Reduced

logistics costs

(OTO India) -

Bulk purchase

of raw materials

(4 production bases) -

Maximized

economy

of scale

Expected effects

Easy to secure customers

-

Mobility parts

Know-how

(26 years) -

Proven Technology

(customer portfolio) -

Easy to respond to the global market

(securing global bases)

Factory 1

Factory 1- Location Dongnai Province, Vietnam

- Area 30,024㎡

-

Main Products

Forging, CHASISS, Gear Speed,

Gear Clutch

Factory 2

Factory 2- Location Vung Tau Province, Vietnam

- Area 33,058㎡

-

Main Products

Forging IVT, CHASISS, Gear Speed,

Gear Clutch

Built additional production facilities for Neooto

- Vacant site in Otovina Facility investment in progress

- Neooto Secured global production base

-

Production Products

-

Transmission Parts

-

Speed Reducer parts

-

Chassis

-

Economy of ScaleRealize economies of scale

when purchasing OTO VINA

and NEOTO raw materialsPossibility to jointly purchase raw materials between adjacent facilities → Realize economies of scale -

Low labor costsLow labor cost base

Secure cost competitiveness- Domestic

- Vietnam

-

Vietnam production plant

When utilizing OTO VINA

Expected effects -

Tariff-free benefits‘20.08 EVFTA

(Vietnam-EU Free Trade Agreement)Recognizes products made in Vietnam

as Vietnamese → Exemption from tariffs

for export to Europe -

Expand global supply chainFacilitating customer

expansion for EU Global

automobile customer

ESG Status

-

- Environment

-

Participating in eco-friendly trends

at home and abroad realizing

- Expanding the use of renewable energy

- Practicing carbon neutrality by introducing solar facilities

Installing solar panels in production facilities-

Annual Electricity Production 97,200kW

-

100% self-consumption of electricity generated without

-

- Social

-

Social enterprise practicing continuous

social contribution activities

- Continuous social contribution

- Active sponsorship and volunteer activities in the local community

Regular volunteer activities in the local community

Regular sponsorship in the local community

-

- Governance

- Implementation of ethics and compliance

- Compliance with fair trade

- Establishment of internal regulations for fair trade

- Establishment of ethical management system

- Establishment of code of ethics and disclosure of ethics policy

- Transparent management

- Operation of channels for reporting corruption and compliance with relevant laws and regulations

- Strengthening shareholder-friendly policies

- Strengthening shareholder return through continuous dividend expansion